One-Stop Custom Cabinet Solutions for Your Project

Design and supply custom kitchen, wardrobe, and bathroom cabinet systems for villa, apartment, hotel, and commercial projects worldwide — with coordinated materials, precision manufacturing, and integrated project support.

Installation-Ready Custom Cabinet Systems

Sibolla Building prepares every cabinet project for efficient on-site installation through in-house pre-assembly checks and engineering verification. Each unit is dry-fitted, hardware tested, and connections reviewed before packing, ensuring dimensional accuracy and installation compatibility.

With labeled components, organized packing, and installation guidance provided, our cabinet systems arrive project-ready — reducing on-site adjustments, saving labor time, and minimizing installation risk.

Custom Cabinet Manufacturing Cost Guide

Key Factors That Influence Manufacturing Cost

Custom cabinet costs are calculated based on production specifications and engineering requirements, including:

Dimensions & Structural Complexity – height, depth, corner units, islands, special structures

Material Configuration – board types (MDF, plywood, melamine) and surface finishes (PET, lacquer, veneer, solid wood)

Hardware Systems – standard soft-close or upgraded functional hardware

Functional Components – pull-outs, organizers, lift mechanisms, integrated accessories

Worktop & Surface Options – quartz, sintered stone, granite, laminate, edge processing

Production & Packing Method – flat-pack or assembled structure, export packing standards

Manufacturing Specification Levels

Cabinet systems are produced under different manufacturing specifications based on project requirements:

Standard – melamine construction, durable surface finishes, functional soft-close hardware

Enhanced – plywood structures, veneer or lacquer finishes, upgraded internal fittings

Premium – designer finishes, solid wood or specialty materials, top-tier hardware systems

Manufacturing Process for Custom Cabinet Projects

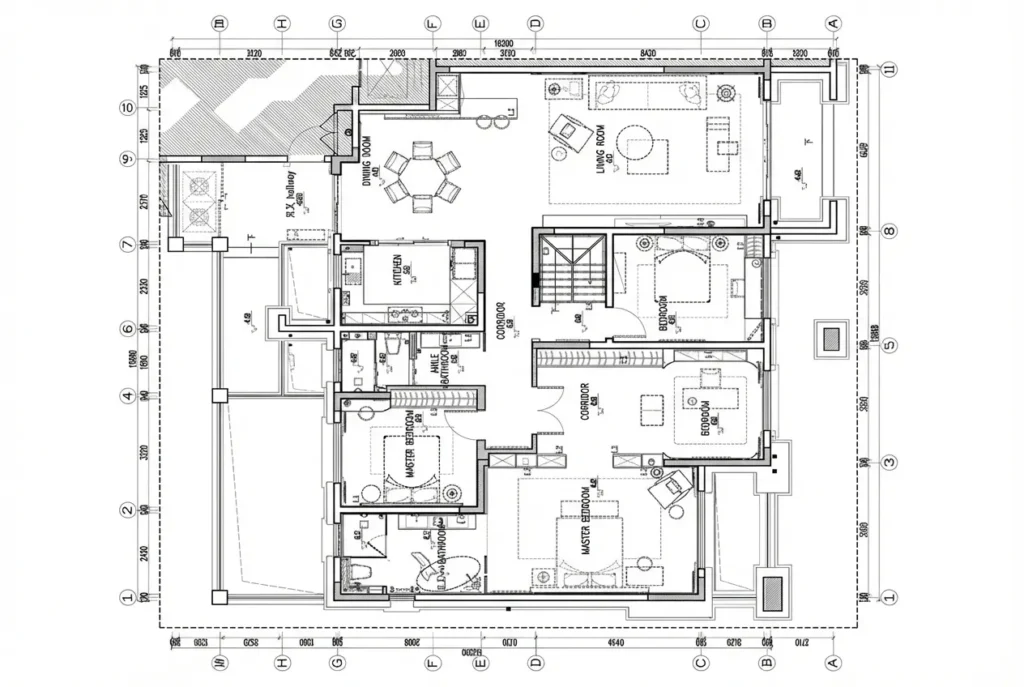

Step 1: Share CAD Drawings & Get a Quote for Custom Cabinets

Upload your CAD drawings (DWG/DXF) and BOQ to receive a clear plan and price.

As your custom cabinet manufacturer, we review your CAD files, project scope, and finishes, then propose value-engineered options. You will receive a free quotation, a 35–45 day lead-time estimate, and an initial consolidation plan for mixed containers.

Step 2: Design Custom Cabinets Online or Offline (Based on Your CAD)

Project-specific design drawings and samples prepared for your job.

Based on your CAD files, we prepare detailed cabinet drawings and material samples. All structures, finishes, and functional details are confirmed before moving to production.

Step 3: Factory Production and Quality Inspection

Cabinets produced and inspected under factory standards.

Your cabinets are manufactured in our factory using automated equipment. Dimensional checks, hardware testing, and surface inspections are completed to ensure production quality.

Step 4: Packing and Shipment Preparation

Cabinets packed and organized for site installation.

Finished cabinets are labeled by area, packed with export-grade protection, and prepared for safe transportation and efficient on-site installation.

Why Choose Sibolla Building as Your Custom Cabinet Manufacturer?

Custom Design & Engineering

We develop project-specific cabinet designs and engineering solutions, including structures, finishes, hardware, labels, and installation references. Production documents and samples are prepared to support manufacturing and site coordination.

One Manufacturer, No Middlemen

Work directly with our factory team. Design, production, quality control, and packing are managed in-house, ensuring clear responsibility, stable quality, and optimized project costs.

Showroom & Material Library

Our 30,000 m² showroom provides a comprehensive selection of finishes, materials, and hardware systems—supporting material confirmation and value engineering for your project.

Quality Control You Can Rely On

From staged factory inspections to final pre-packing checks, quality control is integrated throughout the manufacturing process, ensuring accuracy, consistency, and installation readiness.

Custom Cabinet Door Material Options

Melamine-Faced Plywood

Melamine-faced plywood combines a multi-layer plywood core with a melamine decorative surface, offering strong structural stability, resistance to warping, and consistent color performance. It is a practical, low-maintenance option for cabinet doors used in wardrobes, vanities, laundry areas, and light-commercial storage applications.

Melamine with Particle Board

Melamine-faced particle board combines an engineered wood particle core with a melamine decorative surface, offering stable structure, smooth finish, and cost-efficient performance. It is widely used for cabinet doors in wardrobes, vanities, and residential storage areas where uniform appearance and functional durability are required.

Lacquer with HDF Panel

Lacquer with HDF panels are manufactured using high-density fiberboard cores with multi-layer spray lacquer finishes, producing a smooth, refined surface with strong dimensional stability and consistent finish quality. Used for contemporary cabinet doors where precise shaping, smooth edges, and high-quality painted surfaces are required.

PET-Faced Panel

PET surface panels use a decorative PET film laminated onto engineered board substrates, providing a smooth finish, color consistency, and good resistance to moisture and everyday wear. Suitable for modern cabinet door designs in kitchens, wardrobes, and residential storage applications where uniform appearance and easy maintenance are required.

PVC Over HDF Board

PVC-coated HDF panels use a decorative PVC film thermo-laminated over an HDF core, offering a uniform surface, good moisture resistance, and easy maintenance. Commonly applied in cabinet doors for kitchens, bathrooms, and utility areas where durability and consistent surface appearance are important.

Solid Wood Panel

Solid wood cabinet doors are manufactured from natural timber boards, offering traditional appearance, material strength, and re-finish capability. Used in high-end residential or classic-style interiors where natural material character and craftsmanship are emphasized.

Cabinet Countertop Material Options

Cabinet Countertop Material Options

Thickness: 15 mm / 20 mm; Depth: 600 mm

Front edge build-up: 50 mm; Rear guard height: 50 mm

Sintered Stone Countertops

Sintered stone countertops offer low water absorption and high resistance to heat, UV exposure, scratching, and staining. The dense, non-porous surface provides hygienic performance and easy maintenance. Suitable for cabinet countertop applications in kitchens, bathrooms, laundry areas, pantries, and other service spaces where durability and surface stability are required.

Quartz Countertop

Quartz countertops are engineered stone surfaces composed of natural quartz aggregates and resin binders, offering high hardness, dimensional stability, and resistance to scratching and staining. The non-porous structure supports hygienic performance and consistent surface appearance. Suitable for cabinet countertop applications in kitchens, bathrooms, and commercial interiors where durability, color uniformity, and low maintenance are required.

Customized Cabinets FAQs

Q:how much do custom cabinets cost?

A:The cost of custom cabinets can vary significantly depending on several key factors: the size of the project, the materials selected, the level of customization, and the complexity of the design. For example, a simple kitchen cabinet setup for an apartment will cost less than a full-house solution for a villa or a commercial project.

Q: Are custom cabinets worth it?

A:Yes—custom cabinets are absolutely worth it if you’re looking for a long-term solution that fits your space, lifestyle, and design vision perfectly. Unlike stock options, custom cabinetry is tailored to your exact layout, offering better space efficiency, higher material quality, and a seamless look that enhances both function and aesthetics.

Q: Are custom cabinets more expensive?

A:Generally, yes—custom cabinets tend to cost more than stock or semi-custom options. However, the higher price reflects the added value: precise fit, personalized design, better materials, and long-term durability. You’re not just paying for cabinets; you’re investing in functionality, aesthetics, and space optimization tailored exactly to your needs. In many cases, custom cabinets can actually save money down the line by reducing waste, avoiding rework, and maximizing usable space—especially in kitchens, villas, and uniquely shaped rooms.

Q: Do custom cabinets last longer?

A:Yes, custom cabinets are built to last longer than most mass-produced options. They’re crafted with higher-quality materials, precision manufacturing, and detailed craftsmanship that ensures durability over time. Because they’re made specifically for your space and usage needs—whether it’s a busy kitchen cabinet or a full storage system in a villa—they’re less likely to suffer from poor fit, premature wear, or structural issues.

Q: How long does it take to get custom cabinets?

A:The timeline for custom cabinets typically ranges from 4 to 8 weeks, depending on the size and complexity of your project. Simple kitchen cabinet orders may take less time, while full-home or commercial builds—such as villas, hotels, or offices—require longer planning and production cycles.We begin production once your design, materials, and layout are confirmed. Our team will provide you with a detailed schedule and keep you updated every step of the way to ensure timely delivery.

Contact Us

We’ll get back to you within 24 hours. For urgent project inquiries, contact us directly at +86 13695169816. You can also upload your project drawing files